Not until the sixteenth century were money chests and cash boxes first forged completely in sheet iron and reinforced with intersecting strips and fittings made of iron. They were forged by skilled blacksmiths in southern Germany, Austria and France. Their sheet iron chests were the models for the mass-produced money chests of the nineteenth century.

Southern German blacksmith shops, Augsburg and Nuremberg

In the fifteenth and sixteenth centuries, a host of cities in southern Germany, Austria and Switzerland were renowned for their craftsmanship, especially Augsburg and Nuremberg. The latter had more than 140 crafts registered at the end of the fifteenth century.

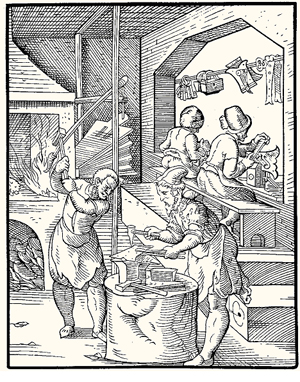

Blacksmiths and their workshops were organized in the cities’ guilds with a monopoly on production of iron objects. Apprentices and journeymen trained with the master blacksmiths.

The shops were usually old family businesses in which younger generations were trained by their elders. They became extremely skilled blacksmiths, along with equally skilled colleagues in specialties such as sheet metalworking, etching, hammered inlay, steel-plate engraving, painting and rustproofing. By the dawn of the Renaissance they had already achieved a strong tradition of craftsmanship and a dominant position in Europe. The immense and well-planned production of these shops cannot be considered merely an early proto-industry.

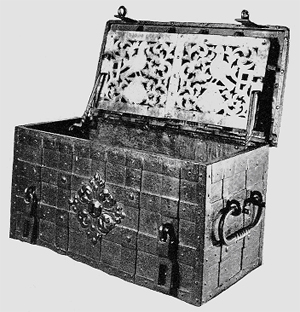

|

| Money chest made in the seventeenth century in Nuremberg, Germany. The lock is protected by an ornate, decorated cover. The chest has a magnificent but false keyhole on the front and fittings for two padlocks. Photographer unknown |

Forging production in certain cities focused mainly on steel and iron armor, as well as equipment for entire armies of foot soldiers, cavalry, officers and horses. Blacksmiths produced all types of small arms for the era, along with accessories, swords, rapiers, lances, helmets, breastplates, armor and special equipment for tournament games. The high precision required for weaponsmithing was attained through technical skills and the shops achieved the highest quality in Europe. Parade armor purchased from Augsburg in 1540 for Gustav Vasa is on display at the Royal Armoury in Stockholm. The lock on his gold-plated wheellock rifle was made in Nuremberg that same year.

During the early sixteenth century, new requirements were introduced with new forging technology. In addition to the ordinary smithing with hammer or sledgehammer, the work was completed at the bench with laborious file work, using a vise. The craftsmen used a large set of files to create smooth surfaces and precise angles, followed by finishing and polishing with polishing steel. The files, which the gunsmiths and locksmiths usually produced themselves, were their most important tools.

Demand and production of locks and chests was surprisingly large. Chests and boxes were in demand far beyond the borders of the German states. Many of them found their way to Scandinavia. The appearance of chests and boxes was adapted to the application – from simple strong basic boxes used as money chests to hold taxes, tariffs, and soldiers’ wages, to decorative chests and boxes for gift-giving purposes. There were two types of German chests for soldiers’ wages: south German and Swiss. They were four-sided with heavy locking lids, reinforced bottoms and strong handles. The Swiss version also had double walls.

Locksmiths were attracted with offers for forging work at the courts of emperors, kings or princes in their own kingdom or other German empires or kingdoms, or even abroad. At that time, locksmiths from Germany worked in the service of the crown in Sweden.

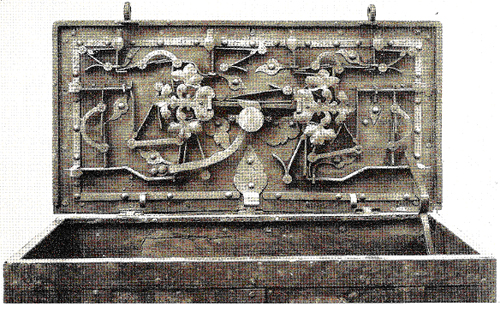

|

| Lock with eight lock bolts in three directions built into the lid of a seventeenth-century south German money chest. The keyhole with a box of wards is always placed in the center. Nordiska museet (Nordic Museum), Stockholm |

The blacksmiths did not take their products to markets. Commerce was handled according to the “putting-out” system by merchants, or “putters-out,” who provided the capital necessary for an occupation or business. The products served as collateral for this loan. The putters-out were on contract to provide the workshops with the cash or raw materials they needed, and in return they had priority to the goods produced. The putters-out obtained the raw materials the blacksmiths needed from the blast furnaces and ironworks forges of nearby mines.

At that time, money chests were usually made with an unembellished interior. Externally, however, they were usually extremely lavishly decorated with painting, ornaments, chasing, etching, gilding and sometimes with welded brass details.

|

| Money chest, seventeenth century. Hanns Schell Collection, Graz. Photo by the author. |

However, there were chests with slide-out drawers (cabinets). The entire front of such chests could be opened, with two locking doors with built-in locks.

Money chests and cash boxes had widely varied locking devices; there could be one or more padlocks and a small fixed lock, or complicated locks with many bolts built in that fill the entire underside of the lid. In the latter case the keyhole was always positioned in the center of the top of the lid, well hidden through some cleverly designed camouflage or extra function. The strong key had a stable bit that locked all bolts with a single turn; in other words, it was able to overcome resistance and friction in all springs and moving parts. During the seventeenth century, locksmiths also began to cover the lock device with a painted or decorated and ornate removable cover of polished sheet iron.