Private company

Anders Johan Gustafsson was also infected by the entrepreneurial zeitgeist, and quit his position at Husqvarna in 1871 to found his own drop forge workshop with his younger brother Carl Albrekt, also a smith, who had recently left Eskilstuna to team up with his brother as master blacksmith at Husqvarna. They both headed for the Domneån river, which runs through Habo and Bankeryd.

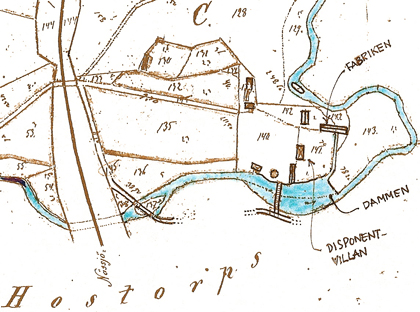

The waterfalls along the Domneån river from Klerebo to Aledal make up a total drop of 98 meters. Waterwheels had been used there since the 1600s to power mills, sawmills, planers, forges, drills and grinders. Eventually, the brothers chose the site of one of these former grinding workshops called Kroken. As early as 1813, Husqvarna Faktori had leased the site from the Attarp estate, and towards the end of its life, it had been used for grinding bayonets. However, the building was in such poor condition that only its stone foundations could be used for the new factory, and possibly the water channel from the dam to the waterwheel.

|

| The Aledal factory, 1885 |

Buildings

The first factory building, which was extended in 1895, was erected on the site of the disused grinding workshop and remained in its original form until the fire of 1976. The timber walls facing the road were clad with vertical paneling and painted in the traditional “Falun” red color with white trim; the other faces were left bare. The windows were large with white frames, each divided by bars into twenty separate panes. The roof was covered with tiles.

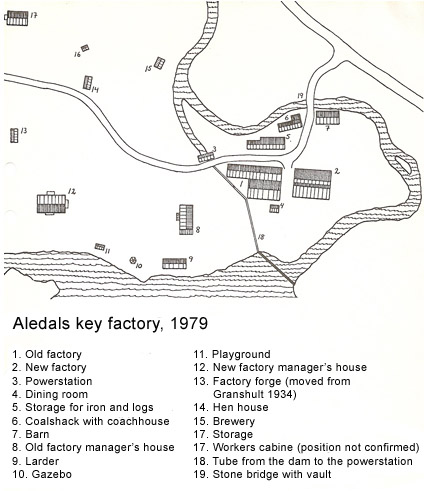

|

| The size and position of the buildings in 1979 |

The other buildings that were built over the years on the site were constructed in the same way. Eventually, the office was housed at the back of the main building, which lay with the same orientation as the bridge over the Domneån river. It had a raised ridge and a skylight turret with low windows. The office’s main window consisted of one large pane. The building had a loading ramp along the side facing the bridge.

|

| The old and new factory buildings. Photo from the 1943–44 production catalogue. |

Anders Johan Gustafsson and family

Anders Johan Gustafsson was the oldest of seven siblings (two girls and five boys), all of whom lived to adulthood. It seems to have been a natural assumption that his brothers would also train to become blacksmiths, and for a while three of them were engaged at Husqvarna. In 1881 or 1882, after tense relations, Anders Johan bought out his brother Carl Albrekt’s share of the business and gave him the idea of opening a scissors forge at another waterfall higher up the river, which came to be called Alefors.

A general recession hit Sweden in the 1880s, forcing Anders Johan to lay off employees at his company in Aledal. He also fell ill with pneumonia, and this, compounded with a profound depression, eventually led to his suicide in 1892.

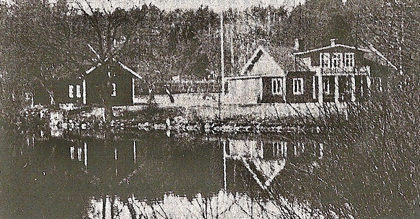

|

| The General Manager’s house before the fire of 1989. |

The General Manager’s house

As buildings at the nearby Attarp estate were being demolished, the brothers bought one of the wings, which was dismantled and rebuilt in Aledal as their home. The house was modernized in 1907 and fitted with electric lights.

The Nya Ale building burned down in 1989, but was rebuilt in its original form.

Workers’ residences

The old Norget building contained four one-room flats for the ten or so employees. When the workforce grew, new Norget was built to accommodate them.

Water power and the power plant

In connection with the establishment of Aledal, Anders Johan rebuilt and expanded the old dam and added a waterwheel to the factory building to power the machines via belts from transmissions suspended from the ceilings. For the first few decades, manufacture was completely dependent on the water supply in the Domneån river, so if the water was low, there were stoppages and delays.

Machines

The inventory of Anders Johan’s estate in 1892 shows that the factory’s machinery comprised three drop hammers, four eccentric presses, a transmission line with belts, and a scouring barrel.

|

| Interior of the drop forge from the early 20th century. Note the transmissions on the ceiling. |

Production under Anders Gustafsson

For the first few years, Anders Gustafsson worked in part at the Husqvarna Faktori along the lines of the “putting-out” system. In the rifle-making business, this involved the masters collecting the necessary material at the factory and supplying the finished products against payment. They kept regular accounts of the material and the delivered rifles and the payment received for them. Many of them owned forges, tools and accommodation, and normally a farmed smallholding as well.

But the most important products at Aledals Nyckelfabrik were keys. They were mass-produced using a drop forge, which meant that their shapes and sizes had to be standardized. There was great resistance to this; the scissor and key-makers of the 1850s only grudgingly began experimenting with drop forging, a simple method in which the smith placed a malleable lump of hot iron between two dies or molds, then pressed them together under the enormous weight of the drop hammer.

The lower die was made using a key-shaped upper die, which was pressed into a soft mold to leave an impression of the key. To make a key, the molten iron was drawn over the lower die, the upper die was placed on top, and the heavy hammer was dropped, molding the iron into the desired shape.

Aledals Nyckelfabrik used a 1930s drop hammer weighing about 500 kg from Munktells in Eskilstuna and another drop hammer of around 250 kg.

|

|

| Lower die. Photo by the author. |

Drop-forged key blanks with burring. Photo by the author. |

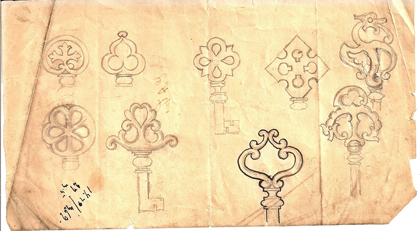

Anders designed and made machines and certain products, and took out patents. Along with rifle barrels and other weapons components, he made pistols and revolvers of his own design. Keys he made on commission using the customers’ drawings, producing special orders of his own design only on exceptional occasions. Later, these products were joined by general building hardware as well as his own patented steel combs.

|

| Unused sketches for key grips for furniture locks. |

Competition

During the latter half of the 19th century, Eskilstuna found itself home to many different lock companies, two of which, in the early 1900s, started to manufacture the keys to their own locks. One of these companies was A Th Broms, which seems to have copied the entire Aledal drop-forged key concept.