The Polhem lock contains a number of components made of steel plate from the company’s own rolling mill and forged details. The lock consists of a lock body, revolving discs, wards, a shackle with a locking washer, and a key.

The lock body contains several metal discs stacked on top of each other. Alternate discs are fixed or free to revolve. In the center of the lock body, they form a rectangular hole for the key. The outer edge of the revolving discs has two diametric indents for both legs of the shackle. The key, with teeth and incisions, is inserted from below and can only be removed in a locked position. By turning the key, the revolving discs are moved to the locked position and the legs of the shackle cannot be pulled out. By changing notches and the number of discs, a large number of combinations are possible.

Shackle

The shackle has two shafts with teeth of different lengths. The shackle was forged of steel and filed smooth, and the different notches in the shafts were made using a file. The article number and brand name were stamped onto the same side of the shackle. Once the shackle was inserted into the lock body, the locking washer was fitted into the tip of the longer shaft. It was then heated and forged into place.

Variation 1: No article number or brand name.

Variation 2: After the 1850s, the “tail” on some Polhem locks was replaced by a hinge joint – as used in modern padlocks today.

Variation 3: After 1850 the article number of some locks was stamped into the bottom of the lock body.

Revolving discs

The steel plate was shaped in a rolling mill and the revolving discs were perforated in a machine to a predetermined pattern that corresponded to the notches on the key bit, with a rectangular hole in the middle.

Upper and lower plates

Upper and lower plates were rolled and stamped out in a machine. In the center of the upper plate a hole was punched for a ward (corresponding to the drilled hole in the bottom edge of the key), which was riveted into place.

Variation: No ward.

Lock body

The material was rolled to a thin sheet, 0.8 mm, although slightly thicker (1 mm) for the two smallest types of locks. The various recesses were then shaped while the sheets were hot. The heated plate was then curved around an iron rod and the joins were heated or soldered together.

Variation 1: The joins were made at various places on the side of the lock body.

Variation 2: When the locks were fitted with a hinge joint, the sheet metal was riveted into place with it, leaving the join open.

Variation 3: In the latter half of the 19th century, a new type of lock body was designed for these “Scandinavian padlocks.”

Assembly

The bottom edge of the lock body was turned (bent) inward all the way around and the revolving discs were placed into the lock body between the upper and lower plates. The upper edge was then turned in the same way and hammered into place.

Variation: The top plate of the lock body was secured by heating it, which is why only the bottom edge of the lock body was turned (bent) in over the lower plate.

|

| Key to a Polhem lock from the latter half of the 18th century. Photo by the author. |

Key

These peculiar keys were forged in one piece and filed. The notches in the key bit were made using a file and holes were drilled into the bottom edge of the pipe for the ward. Holes were also made in the top edge of the bow.

Variations: The bows on the oldest keys are pear-shaped. In the early 19th century, they were made as circles, and later ovals. From the mid-19th century, they were made of cast iron, brass, or a combination of the two. Drop forging techniques were also used on some locks. The bow was produced in new designs – some without holes for the ward.

|

| Key to a Polhem lock from the early 19th century. Photo by the author. |

|

| Keys to Polhem locks from the latter half of the 19th century. Photo by the author. |

Polhem’s other padlocks

Polhem’s locks were developed during the latter half of the 19th century, gaining lock bodies with hinged shackles, new types of keys, cylinders, and new shapes.

At the end of the 19th century, American Linus Yale started manufacturing padlocks based on the Polhem lock. He called them Scandinavian padlocks or American locks. Yale’s versions do not have the classic “tail” of the Polhem locks, though. The keys have the same type of bit as the Polhem lock, or individual variations of it.

|

| Keys to Scandinavian/Polhem locks from the early 20th century. Photo by the author. |

|

| Scandinavian/Polhem locks from the early 20th century. Photo by the author. |

Competition

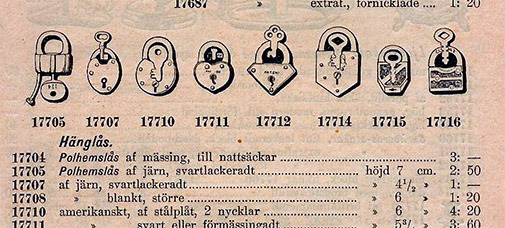

A product catalogue from 1904, entitled Köpmannens rådgifvare (“Merchant’s Advisor”), tells us that Polhem locks were still manufactured and sold at that time.

The Stjernsund works was not the only place in Sweden that made Polhem locks. The invention was copied, and from the end of the 18th century, similar padlocks were made at various locations in the country – most of all in Eskilstuna, west of Stockholm.

|

| Polhem lock by Adolf Ståhl, Eskilstuna. The largest is 15 cm high and 6 cm wide. The small one is made of brass and is 3.8 cm high and 5.5 cm wide. Photo by the author. |

The locksmiths in Eskilstuna added their names to the locks: Backlund, M Edlund, P Eklund, John Hedlund, Hellberg, A Jäderlund, Adolf Ståhl, Lars Ström, J P Häggvall, Joh Wahlén and E Otto Grytzell.

In Jönköping, such locks were made by a locksmith named Malmsten.

|

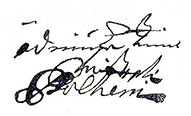

| Christopher Polhem’s signature from a letter that he wrote in 1718 (the Swedish National Archives). |