|

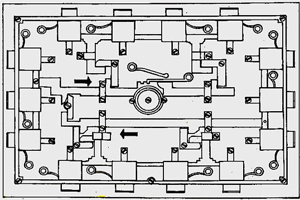

| Example of a somewhat more modern lock built into a chest lid. The key, which is placed in the midpoint, controls 14 short bolts in four directions via the two centrally placed bolts and actuators. Plate from Comte de Grandpré, Manuel théorique et pratique du serrurier, 1830 |

This specific type of chest has sides covered with rolled sheet iron reinforced with intersecting narrow nailed iron strips. All angles are covered with edging that form a frame held together with iron rivets. In some places dome-shaped rivet heads are used. The lid is also made of plate and is completely plain, or reinforced with intersecting narrow steel strips. It is also attached to the chest at the back with two strong hinges. The heavy chests required strong handles on each gable. The base color is always green and the strips are usually black.

It is believed that master Willem in Nyköping brought the practice of rolling iron into plate to Sweden in the early seventeenth century. Subsequently more rolling mills were established that could provide black plate to tinsmiths and locksmiths.

Iron chests are not particularly safe from the standpoint of fire. When heated, the paper inside the chest chars and in strong heat the chest can melt. In order to delay the effect of the heat on the contents to some extent, some chests in the late nineteenth century were made with double plate walls separated by, for example, about a 2 cm-thick layer of cork.

Locking devices

Locking devices vary; the lid is usually locked with some form of locking device built into the lid and supplemented with one or usually two padlocks via the flap mounted on the front edge of the lid and corresponding with staples on the upper edge of the chest.

The lid is locked with a padlock using a fitting attached to the lid with hinges adapted to the corresponding one or two staples on the upper edge of the front sides. Sometimes they are fitted with false keyholes on the front sides.

The lid lock was attached to its underside and the key controlled from the upper side of the lid by lock bolts under a strip on the upper edge of the sides of the chest.

1. The lock may be a tumbler lock with two or three lock bolts built into one (or two) plate box(es) (lock body), nailed to the underside of the lid, with keyhole that sticks out on the upper side of the lid and is protected by a flap.

2. However, the locks can also be more complicated, covering the underside of the lid with several bolts in three or four directions, which are controlled by a centrally placed key. This type of lock can have an extra function alongside the central one, which is controlled via a secret camouflaged, ornamental detail.

|

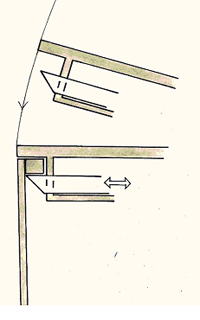

| Principle for self-locking lid. Locks against the strip that reinforces the upper edge of the sides of the chest. Bolts without beveling also use the same type of strip when locking. Sketch by the author. |

|

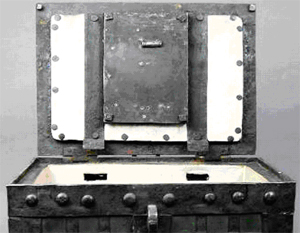

| Built-in tumbler lock as trunk lock. Screwed onto the underside of the lid with keyhole on the upper side of the lid. Göteborg City Museum. Photo by the author. |

|

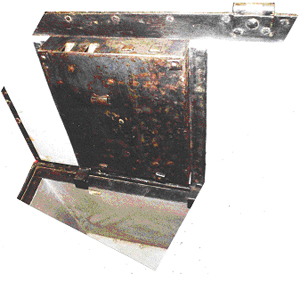

| Lock built into the lower edge of the lid. Four bolts, two of which are beveled. Göteborg City Museum. Photo by the author. |